The morning mist nonetheless clings to the rubber bushes as Moses Dolo makes diagonal cuts to gather the milky latex that seeps from every incision.

By Joeraisee Joe, contributing author

The work is relentless, however tapping has lengthy been a part of Dolo’s life. By Could, he had practically three tons of latex, sufficient to generate about $1,500. “Rubber farming is labor-intensive,” Dolo stated. “If you wish to earn a revenue as a smallholder, you want to be concerned in tapping, not simply depend on employees.”

However simply as Dolo was about to promote, devastating information was not distant: Firestone, the nation’s largest rubber purchaser, was suspending all rubber purchases nationwide, citing the federal government’s mandated pricing as “unsustainable.”

“I had grown used to the uncertainties of the enterprise, fluctuating costs and irregular consumers,” Dolo remembers, the reminiscence nonetheless painful months later. “However nothing ready me for what occurred in June. This time I had sufficient latex, about three tons, representing not simply misplaced earnings however wasted labor, supplies, and hope.”

For many years, smallholders had confronted this precarious actuality, as Firestone would periodically halt purchases primarily based on market circumstances, forcing farmers to simply accept considerably decrease costs from middlemen. That modified for Dolo in August, when a pal informed him in regards to the Jeety Rubber Manufacturing facility in Weala, Margibi County.

The sprawling $35 million facility requires a each day minimal of 200 to 250 tons of unprocessed rubber to function at full capability of 25,000 tons yearly. The manufacturing unit, exporting Technical Specified Rubber (grades TSR10 and TSR20), buys practically all of its annual rubber wants straight from smallholders on the authorities market worth of $574.06 per ton of coagulum (cup lumps or slabs).

“The manufacturing unit is a blessing. We not fear about whether or not Firestone will purchase or not,” says Dolo, who’s from Todee, Montserrado County. “The added benefit with Jeety Rubber is that whenever you take your rubber to them, they pay money instantly. There isn’t a going backwards and forwards. It’s direct.”

Dolo’s reduction is shared by tons of of smallholders who would in any other case be struggling. He says Firestone’s buy suspension just isn’t hurting smallholders, as there’s a alternative with fixed demand for latex. The pricing construction, launched in June, set $574.06 because the gross worth for a ton, together with a 4% authorities levy of $22.96, with contributions to the Rubber Growth Fund Included ($3.17) and the Rubber Planters Affiliation of Liberia ($2.00), leaving smallholders with $545.93 internet.

Officers characterised the pricing choice as defending smallholders from exploitation whereas restoring equity to a sector lengthy tormented by unstable pricing. The federal government says its market worth, which is topic to vary relying on market circumstances, was set towards the typical each day worth of rubber on the Singapore Commodity Alternate for every previous month, with regulators deducting manufacturing prices to mirror the 58% dry rubber content material and making use of a ten% revenue margin for processors, resulting in the ultimate gross worth.

Consultants notice that the federal government’s involvement was essential to stop exploitation of smallholders, who’ve been price-takers for too lengthy. The fastened pricing, consultants say, offers smallholders dignity and predictable earnings, making a sustainable enterprise mannequin that advantages everybody within the provide chain.

In contrast to Firestone, Jeety Rubber depends virtually solely on smallholder manufacturing. Its acquisition of the 4,400-hectare Salala Rubber Company can not meet the manufacturing unit’s latex necessities alone. Business consultants predict that because the manufacturing unit expands, each day latex wants may attain about 400 tons, creating unprecedented alternatives for smallholders.

Based on Merey Napal, within the final decade, rubber farming has been a chance, by no means realizing if consumers would come or at what worth. Nevertheless, the dynamic appeared to have modified because the Jeety Rubber manufacturing unit’s starvation for latex has created a lifeline marketplace for smallholders from Montserrado, Margibi, Bong, and Nimba counties.

“For those who or your employees are sturdy sufficient, and your bushes aren’t too outdated, you may promote three tons weekly, that’s $1,722 or extra month-to-month,” she calculates, her voice reflecting newfound confidence within the sector’s prospects.

“The revenue margin within the rubber enterprise is small, however with fixed gross sales, that’s whenever you see revenue. That is what makes Jeety Rubber a dependable accomplice. You carry rubber, they purchase, and pay money instantly,” says Napal, who in August alone visited the manufacturing unit twice to promote.

Jerry Sumoward shares this optimism. He remembers how smallholders had misplaced religion in farming as a result of Firestone’s unpredictable buying suspensions that devastated incomes and livelihoods. Based on Sumoward, the demand for rubber from the Jeety manufacturing unit has led to a shift in smallholders’ mindset—from survival mode to long-term financial planning, specializing in replanting and workforce funding to spice up manufacturing.

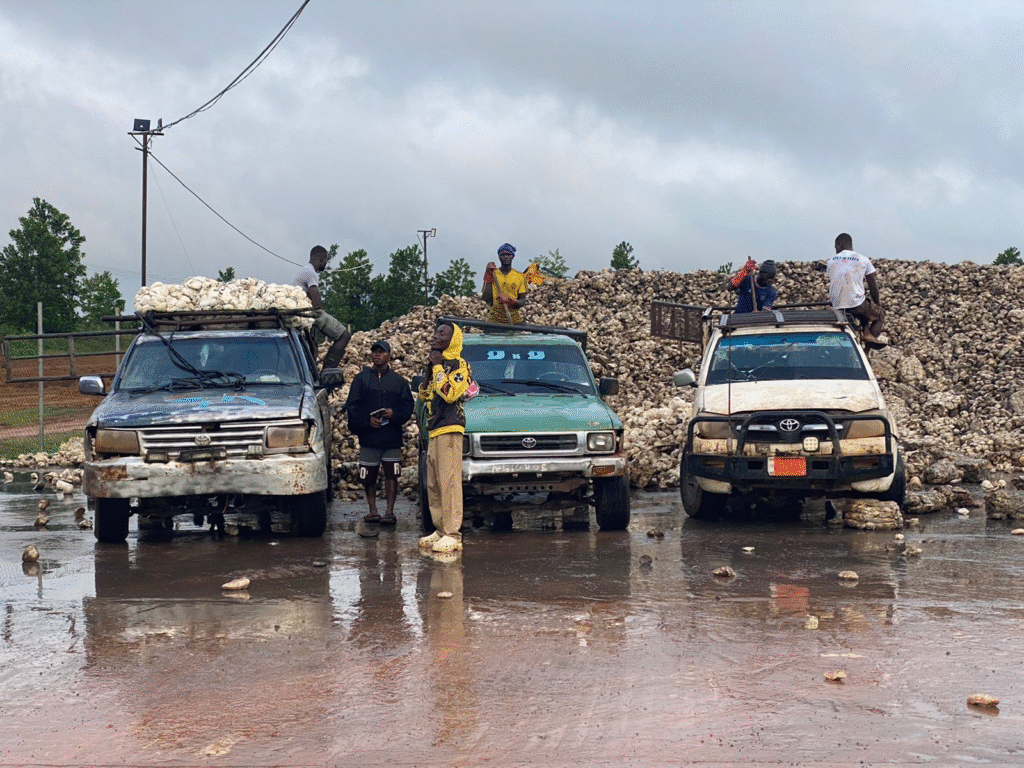

“Lately, many farmers have begun replanting, which is great for long-term sustainability,” Sumoward explains whereas weighing practically 11 tons of rubber in Jeety’s manufacturing unit yard. “This wasn’t a precedence when the enterprise wasn’t worthwhile, however now it’s.”

“Rubber farming is pricey, so with out fixed demand, smallholders’ incomes and livelihoods undergo badly. However now, we anticipate a greater future,” he says.

Sumoward’s optimism comes as Jeety is spending roughly $114,812 each day buying 200 tons of latex, averaging $803,684 weekly. The corporate is predicted to spend $24 million from June to December, shopping for on the authorities worth of $574.06.

This provides to the over $20 million spent up to now 18 months buying from smallholders on the firm’s earlier fee of round $400 per ton. The corporate tasks annual rubber buy expenditures of $40–50 million as soon as it begins producing rubber items within the subsequent two years.

Regardless of excessive demand, the manufacturing unit nonetheless struggles to safe the 25,000 tons wanted for full-capacity operation. Consultants attribute the shortfall to declining latex manufacturing, as many bushes in main rubber-producing counties are previous their prime. Based on the Meals and Agriculture Group, latex manufacturing declines considerably after 30 years, rendering additional tapping uneconomical, although smallholders could proceed for years past optimum productiveness.

And as international pure rubber demand grows, pushed partly by environmental issues about artificial alternate options, Jeety Rubber and smallholder have developed plans to extend manufacturing.The technique consists of offering financing assist to smallholders for replanting and farm growth with improved varieties. The interest-free funding is repaid over 4 to 6 months or yearly, deducted by agreed percentages from every sale.

Hawa Singbeh, a smallholder from Todee, Montserrado, views this assist system as transformative for long-term financial planning. Hawa says that earlier than, smallholders may solely take into consideration as we speak’s issues—the place to promote and what worth to get.

“Now, with the corporate’s assist, I’m replanting and increasing my farm. They provide us cash upfront and take it again slowly from our gross sales. This assist helps us put together for the long run,” she continues. “My kids can see that rubber farming has a future now. With higher bushes and regular consumers, we are able to construct one thing lasting.”